From the "Steam in the Garden" Magazine Cover to the Workbench

By Howard Maculsay

All photos by the author except were noted.

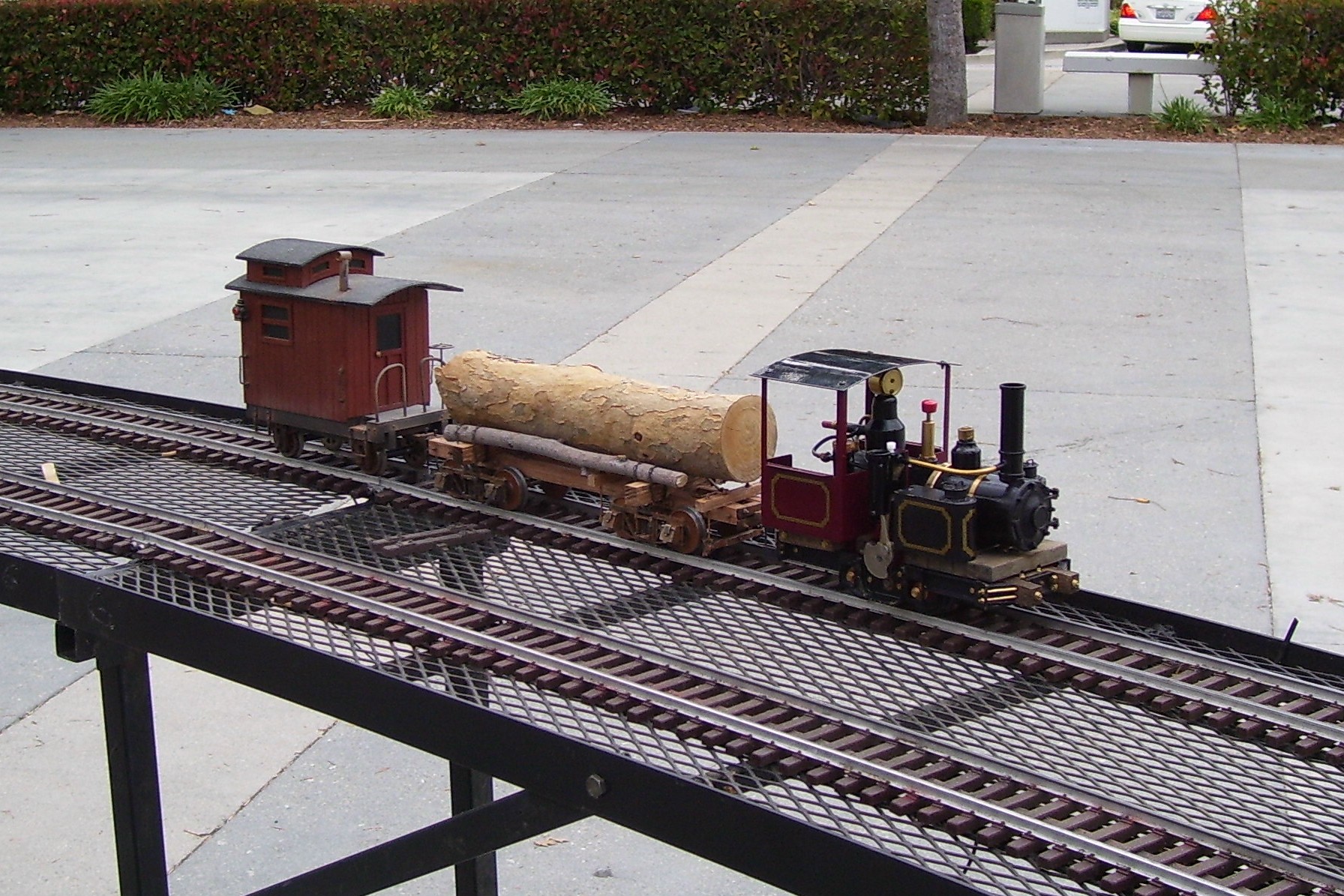

I’ve been experiencing that urge to build a few new pieces of rolling stock for my Narrow Gauge live steam locos. Then on the cover of the last SitG (#103) magazine, there was my inspiration. A bevy of log cars just right for my Cricket or my yet-to-be finished Class A Climax.

Searching the internet turned up some log car pictures. I decided on Hartford Products K-38, Russel No. 2 Pattern Log car ( www.hartfordpr.com/k38.htm ). Hartford’s kit is based on the prototype log cars built by Russel Wheel & Foundry Co. which sold to more than 300 logging railroads. Of course, I will be scratch building most of the log car, but I will purchase the truck, brake, & coupler castings. Dimensionally, I decided on a 20 foot, 15 ton, narrow gauge log car with 6”x 8” stringer timbers & 8”x 8” log bunkers.

Hartford Products catalog picture of the K-38 Russel log Car.

The 1:20.3 scale fully sprung truck set castings and wheels are from Ozark Miniatures

OM # 1066 with a prototypical wheel size of 24”.

Ozark Miniatures catalog picture.

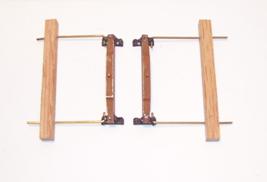

The brake beams and brake shoe castings are OM #1024

are suspended  from

brake hanger beams on one truck only. Ozark Miniatures

catalog picture.

from

brake hanger beams on one truck only. Ozark Miniatures

catalog picture.

The brake wheel and supports are OM #0038 & #1026, resp. to be

mounted horizontally under a stringer.. Xed-out parts

were not used.

Ozark Miniatures catalog picture.

And finally, I decided on using a sprung draw bar link & pin couplers with draft gear OM #0022.

Ozark Miniatures catalog picture.

The wood parts will all be cut from Red Oak. With the exception of the NBWs and Bolt Plates, all other parts will be made from brass.

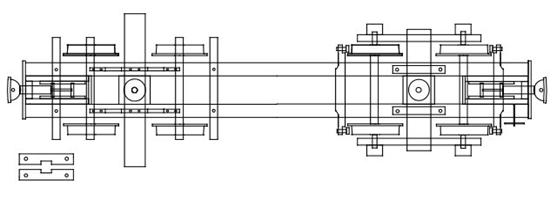

Here’s my working drawing:

The 2 oak stringers are 5/16”x 7/16”x 12” long separated by an oak stretcher (3/4”x 5/8”x 7/16) at each of the truck’s bolster pivot points. This is where each truck is bolted to the frame. Two log bunkers are 1/2”x 1/2”x 3.5/8” long oak. (shown in the drawing over the left end only for clarity sake). Two brake hanger beams are 1/4” square oak by 2.3/4” long and are needed only on the truck that has the brakes. Again for clarity sake, the brake beam & shoes are shown with the truck drawing (right end), but they belong with the truck that has the brake hangers.

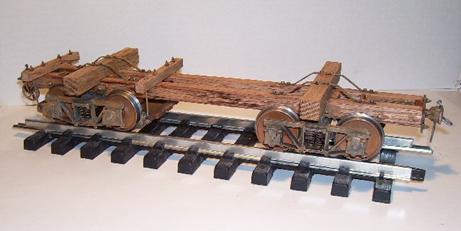

At this point the frame’s oak parts were assembled using brass escutcheon pins and CA’d. The holes for each truck’s pivot points were drilled through the center of the 2 stretchers, using a 9/64” drill bit. I counter-drilled each top side of the stretcher with a 1/2” spade bit, 1/16”deep to receive a 6-32 tee nut which I pressed into the oak with a small C-clamp. The bottom of the log bunkers were mortised to fit down 1/8” over the frame.

The truck’s wheel sets were painted with Badger’s Model-Flex “Rust”. The axle’s bearing surface and where the wheels contact the rails were all left unpainted.

After cleaning up the flash from the truck’s castings, (side frames, top bolster & journal covers) they received a chemical blackening and assembled with the wheel sets.

The same treatment was given to the brake wheel and its supports and then assembled. The brake beam casting has a wood grained surface so it was painted to resemble an oak color and assembled with the blackened brake shoes. I used 1/16 brass rod for the hangers, but as shown here, still have to be shaped & adjusted to their final length once the hanger beams get mounted on the frame stringers.

The draft timbers for the couplers, adjacent to the draft gear are 1/8”x 3/8’x 1.5/8” long and the 3 cross-braces are cut from 3/16”x 1/8” stock. The length of the cross braces are long enough to position the draft timbers to fit snuggly between the frame’s stringers (about 5/8”). The castings associated with the coupler, drawbar and its draft gear were also chemically blackened and then assembled with the draft timbers and cross-braces as a sub-assembly. The nut for the draw bar’s was secured by a little Loctite (blue) to prevent loosening.

Two brass wear-bearing surfaces (.064” x 3/16” x 1.1/4” long) are escutcheon pinned & CA’d to the top each of the oak frame stringers for each of the truck’s top bolster. These bearing surfaces are left unpainted.

Then one of the assembled trucks was bolted to the frame at the pivot points, using 6-32 screws. A dab of Loctite (blue) on the threads will keep the proper tightness at the pivot point. At this point the brake beam assemblies were slipped onto the stringers, pinned and CA’d. Now the final truck was put in place and secured.

Next came the positioning of the coupler sub-assembly’s height above the track and then CA’d in place. Each coupler has a set of support end plates (.064” x 3/16” x 1.3/8” long) machined from brass, painted and weathered, then CA’d in place at the end of the frame stringers. Each of the log bunkers are secured in place by a pair of 1/32”x 3/32”x 2.142” long pre-formed brass straps, CA’d, then blackened and weathered. The straps were secured to the oak stringers & log bunks using #0 lag screws, 3/16” long.

And now finally, the details, brake wheel and its support assembly, bolt plates, NBWs and the final weathering. The ¾” bolt, 2” hex nuts & washers (NBWs) were used for accents on the Brake Hanger Beams and on the Coupler Draft Gear & its support plates. A pair of Bolt Plates simulating 1.1/4” bolt, 2” nuts on a 6” x 8” pad were used on each side of the 2 stretchers.

I used blackened brass chain to secure the small side logs to the log bunks, which act as a constraint against the log load rolling off the log bunks.

So now you are ready to find a log of appropriate size for your load. I’m using a 11.1/2” long, 2.1/2” diameter branch piece which represents about a 4’ diameter log.

Parts List

1. Fully Sprung Truck Set, Ozark Miniatures OM #1066, 1:20.3 scale, all metal

construction, with 24” Sierra Valley Wheels $ 46.34

2. Brake Beam & Brake Shoe castings OM # 1024 $ 3.70

3. Brake Wheel OM # 0038 castings $ 1.00

4. Boxcar Brake Supports OM # 1026 castings $ 1.15

5. Link & Pin coupler w/ draft gear OM # 0022 castings $ 8.00

6. Blackened Chain OM # 1022 $ 1.07

7. Bolt Plates OM #1012 $ 1.06

8. NBWs OM # 0029 $ 2.46

9. Brass Strap- 12”x .064”x 3/16” & 12”x 1/32”x 3/32” $ 3.00

10.. Hex Head Lag Screws MicroMark #82665 $ 3.50

11. Red Oak- 24”x 7/16”x 1.1/2” & 8”x 1/2” square, &

6”x ¼” square $ 4.50

Total $ 75.78

I’ll be building 3 more of these log cars. Since finishing the first car, I found a new supplier of 1:20.3 scale archbar trucks at about half the price. Needless to say, I’ll be giving these a try. The East Gary Car Company manufactures a D&RG archbar truck kit. It was reviewed in the September/October Sitg, issue# 101.