Paul Mack

In November 2011, I finished working on Laika's Oscar nominated film called 'ParaNorman'. I started on Laika's third project, The Boxtrolls, in January 2012. It is my third stop motion film. The first film I worked on, also as a model maker, was the movie 'Coraline' which came out in February of 2009. I was nominated for an award from the Visual Effects Society for my model making. As a model maker on a film, I make everything from furniture to fully animateable bicycles to the bartender's shotgun. I work with a variety of materials such as wood, plastic, brass, copper, aluminum and steel. I enjoy working with metal and machining using a lathe and mill. I am now also quite proficient at silver soldering (brazing).

This is a photo of me working on Wybie's bicycle for 'Coraline'. It is almost all handmade and mostly metal to survive the rigors of animation. It has front and rear suspension, an electric motor and my favorite, air horns.

Prior to Coraline, I worked as an architectural model maker for 3 years. In that shop I made simple block buildings from basswood or high density polyurethane foam. They were cut on a full size table saw and sometimes milled to more complex shapes. I made more detailed buildings by preparing AutoCad drawings and then using the drawings to laser cut and scribe acrylic sheet. I also worked on fiberglass models for displays in various places around the world including national parks and Portland's own Audubon Society on Cornell. Photos of similar projects can be seen at Rauda's website.

I really enjoy working with metals and here is a pair of earrings I made from the warning label on a lacquer thinner can. They are 0.675" diameter, about the size of a dime.

I have been involved in HO scale model railroading since junior high. These are a few photos of my favorite railroad projects.

I scratchbuilt a 1/87th scale operating model of a coal loadout from a piece of 6 inch pipe and some details I made from materials in my scrapbox. It was featured in the April 2010 issue of Model Railroad Craftsman magazine.

The loadout loads trains with walnut shell "coal". The gate that allows coal to fall into the cars is triggered by magnets on the bottoms of the cars and operated by small motors.

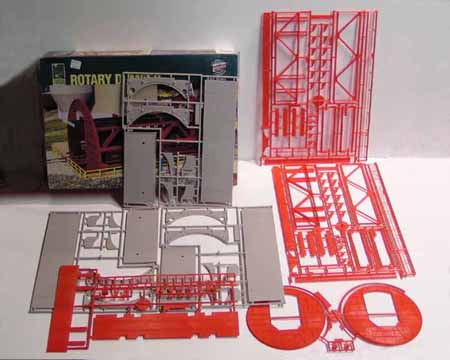

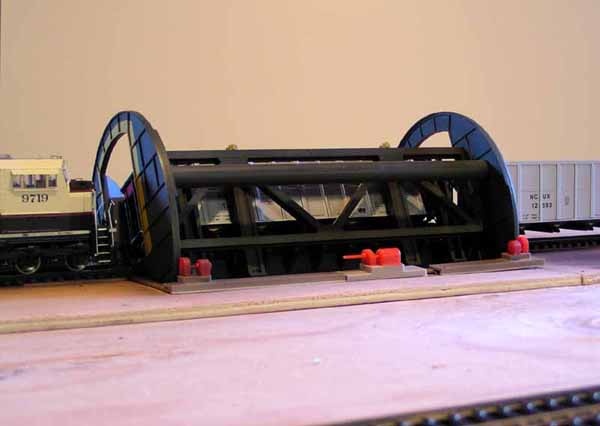

Once the trains are loaded they need to be dumped so I made an operating rotary dumper. It started with a static kit for woodchip hauling railcars.

The addition of parts from an old VCR, retired Burger King display, and EKG machine made the modified kit able to actually dump model railcars.

I am part of a modular model railroading group (everyone builds a section at home, then meets to assemble the modules into a large railroad). I built the bridges from kits and added more detail. I carved the land from scraps of foam and added landscaping. Here are some photos I took on my module and added backgrounds in Photoshop.

An overview of the module on its way to a show. It is 24 inches wide and 54 inches long.

One of the more challenging projects I have undertaken has been a model of the two railcars Boeing uses to transport partially completed fuselages from Kansas to Washington. First a prototype photo:

Next the model photo, obviously still under construction:

The airplane was carved from a block of polyurethane foam and sealed with primer. The long flat car was modified from one commercially available. The supports are scratchbuilt, the one under the main landing gear has nearly 200 individual pieces. The shorter car with the box on the end is scratchbuilt from styrene sheet and shapes. I only had a couple dimensions so most of the project was figuring out what to make by looking at photos.

I also enjoy building models of locomotive from photos. A few before and after photos:

This locomotive belonged to a small railroad where I used to live. To model it, I started with an undecorated shell and rebuilt the nose and added the details including antennae, horns, plow, hoses, grab irons (ladders), bell, air filter, sunshades, vents, working lights, paint and decals. I also bent the handrails from brass wire.

The following model involved more modifications including a rebuilt nose, cab, and electrical cabinet (the area right behind the cab). Before is on the top and after on the bottom.

This page is an abridged version of my web page which has more and larger photos of these and similar projects. I feel I am an accomplished model railroader and the skills I have learned over the last 25 years (9 professionally) of making models has given me abilities I can adapt to many different jobs.